Empowering local energy solutions

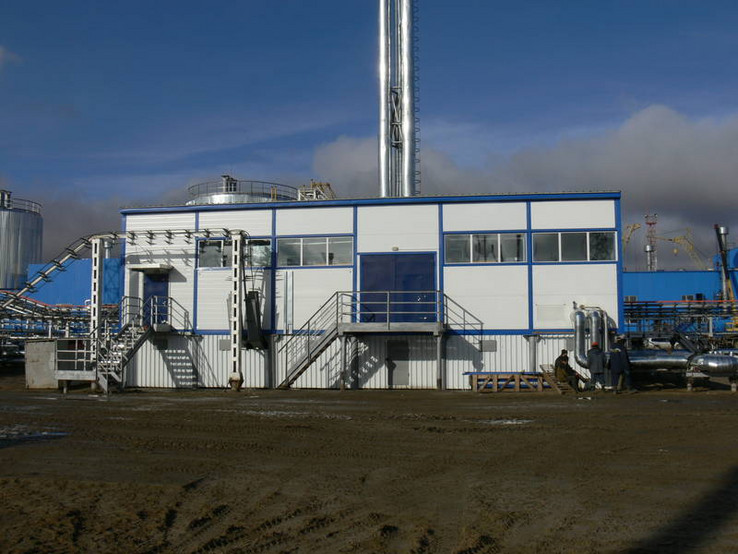

Russia’s reliance on localized power generation represents considerable opportunity for Impuls , which designs and builds (or rebuilds) mini-CHP plants and boiler houses ranging from 0.5 to 200 megawatts.

With its enormous land mass and dispersed population, Russia is a world leader in distributed power and heating concepts: small-scale combined heat and power (CHP) and district heating plants. Russia’s district heating capacity is almost 10 times that of any other country. And there is strong demand for self-contained, mini-CHP plants to provide heat and power for remote production sites in sectors like mining and natural gas transmission. Russia’s reliance on localized power generation represents considerable opportunity for Impuls Industrial Boiler Plants CJSC, which designs and builds (or rebuilds) mini-CHP plants and boiler houses ranging from 0.5 to 200 megawatts. Founded in 2002, the company has pioneered development of modular, fully automated industrial boiler houses that can operate around the clock without staff. ”Using AutoCAD, designing a typical project might take three months or more. With the switch to the EPLAN Platform ... projects of a comparable size covering automated heating systems, power equipment and all instrument and control systems are being completed in 5-6 weeks.” Faster project turnaround with EPLAN

Among the projects completed since the company adopted EPLAN as its computer aided engineering (CAE) platform in 2009, was the reconstruction of Boiler house #24 in Opalikha, in the Krasnogorsk district of Moscow, with a generation capacity of 10.7MW. “The main benefits of rebuilding a boiler house is the enhancement of energy efficiency and reduction of maintenance costs,” says Alexey Soloviev, head of the engineering department at Impuls. “For example, at our Opalikha project, we replaced worn out equipment and improved thermal performance for consumers.” That was a three month job. A completely new boiler house project might take as long as six months from the start of design through commissioning. Needed start of the art design tool

Engineering plays a crucial role at Impuls; over half the staff of 100 are engineers. By 2009, the company recognized its old software tools were too constraining. Engineers were using AutoCAD to design power equipment, automated heating systems and instrument and control (I&C) systems and MS Excel to draw up bills of materials and other lists and tables. Engineers had to connect assemblies and control devices manually. There was no way for the different engineering disciplines to share content or work collaboratively and no way to archive commonly used content. Such data had to be entered manually, over and over again. Cross-referencing and error-checking were extremely labor-intensive and time-consuming. “With so much manual processing, it wasn’t unusual for major errors to creep into projects, a big challenge to fix particularly when projects were on deadline,” says Soloviev. Assembling final documentation packages from AutoCAD and Excel files was another frustration. The documentation for the automated control system and fire response panel of a typical 9MW boiler house project contains over 100 pages. Attracted by EPLAN Platform concept

Seeking to optimize design productivity, Impuls selected EPLAN for its vast automation features and because of it's central data backbone. It’s the only CAE product that fully supports and integrates the electrical, process control and enclosure design tools the company wanted, with 100% data consistency across all disciplines. That, in turn, opened the way for Impuls to restructure engineering workflows to engage in interdisciplinary collaboration. Switch generated major time-savings

“This was a capability the company wanted,” says Alexey Soloviev. “Before we decided to use EPLAN, working in AutoCAD and MS Office meant all product stages were executed by one and the same engineer, because functions like cross-discipline designing and multiple users sharing data were lacking. Now, with EPLAN, the electrical and process control engineers have the chance to collaborate together on projects.” “Projects that typically took three months or more to complete in AutoCAD are being completed in 5-6 weeks with EPLAN – and that became the norm after only half a year using the new software. Engineers are making maximum use of key automation features, like automated error-checking and cross-referencing. Error rates are down, and it’s not unusual to have projects that are completely error-free,” says Soloviev. An archive was created in EPLAN and now contains over 1,500 component macros and 2,000 function macros shared by all disciplines. “We create macros for large object blocks, such as controller modules and control devices,” says Soloviev. “We also create macros for assembly layouts, which we use for manufacturing control cabinets.” Customers like EPLAN results

“With EPLAN,” he says, “there should be a maintenance benefit over time for both Impuls and customers since the documentation generated for each installation is of a higher quality. We have noticed that our customers have far fewer questions with regard to (completed) projects and tend to grade the ones done in EPLAN very well.” Impuls expects that over time, it can accelerate projects further by increasing the number of archived macros and recognizing more ways to take advantage of EPLAN functionality during project development. The support provided by EPLAN Russia in that regard continues to be first rate. “There isn’t a question where the support desk hasn’t been able to help us,” added Soloviev. More than one-third design time reduction

Russia relies a great deal on localized heat and power generation. For Impuls Industrial Boiler Plants, the opportunities for building or rebuilding large boiler houses that provide heat to communities and heat and power to remote industrial installations represents a major growth market. Slowed by using AutoCAD in its engineering, Impuls switched to the EPLAN Platform for its electrical, process control and enclosure design needs. Since then, it has been able to reduce design time by more than one-third. Projects and project documentation are better structured and highly accurate. Now, much less staff time goes into drawing, error-checking, cross referencing, modifications and the generation of documentation. And Impuls continues to add to its archives of component and function macros to further speed up projects by automating the insertion of recurrent content. Find out more about Impuls Industrial Boiler Plants at <link http: www.impulsprom.ru>impulsprom.ru.